You are here

Frozen Ground for Building Support

Frozen Ground for Building Support

Implementation of Innovative Engineering Concepts for Tunneling at Russia Wharf

NAT 2000

North American Tunneling Conference, June 6-11, 2000

ABSTRACT

It is often the owner who starts investigation into innovative construction techniques to gain better solutions for given underground needs, in particular in complex urban settings. In other cases the process may be contractor driven to produce a more competitive bid or offer a value engineering solution. Independent of the initiative, for a successful implementation of innovative techniques a mechanism has to be in place that involves all parties and leads to their agreement to a proposed solution. At Massachusetts Bay Transportation Authority's South Boston Piers Transitway Section 0003A such a process led to implementation of an innovative tunneling scheme which relies on the use of groundfreezing for temporary building underpinning and shotcrete for tunnel support.

1 INTRODUCTION

Tunneling beneath two buildings at Russia Wharf for MBTA's new South Piers Transitway in Boston will call for various means of building underpinning. The tunneling will be carried out using sequential excavation and shotcrete support methods (NATM). All underpinning systems have been designed to enable tunneling within building permissible deformations. The buildings which are founded on timber piles will remain in service for the tenants during the tunneling operation. Underneath one of the two buildings groundfreezing will be used as the sole means of temporary building support while the tunnel excavation will cut through the existing timber pile supports. The frozen soil will encapsulate the timber piles and act as a supporting arch for the building loads above until the cut-off piles are integrated into the tunnel shotcrete lining. After the soil is thawed the tunnel double lining system (shotcrete and cast-in-place concrete lining) will support the wooden piles and perform as a large size strip foundation.

The combination of groundfreezing for underpinning and pre-support together with NATM tunneling constitutes an innovative engineering solution. It provides least disruption to building tenants at economic cost as well as schedule and construction staging advantages. It ultimately replaced other, more traditional design solutions for example one that relied on a large scale steel girder underpinning system with construction of the tunnels in cut-and-cover resulting in the taking of several lower building floors during construction.

Acceptance by all parties however, involved many facets. These initially included a thorough review of relevant case histories, visits to international construction sites, and implementation of expert review boards. Once the engineering concepts were technically accepted, building owner and abutters, in particular the Central Artery / Tunnel Project team, were involved in the design development. Formal peer reviews by outside consultants, contractor pre-qualification and contractor outreach sessions were implemented as part of bid document preparation.

2 PROJECT HISTORY

Located below the historic Russia Wharf complex the Russia Wharf Segment is one section of the Massachusetts Bay Transportation Authority (MBTA) Transitway project. Connecting the South Boston Piers/Fort Point Channel area with the Central Business District the Transitway project has an important role by connecting a fast growing development area to the public transit system of the Greater Boston area.

In 1987 the MBTA initiated a feasibility study that provided a preliminary evaluation of new public transit service alternatives to meet the future travel demands in the South Boston Piers/Fort Point Channel Area. Alternatives included conventional surface bus service, elevated and underground people mover alignments, elevated guided busses, and a relocation of the existing Red L in.-. As a result and as recommended by the feasibility study a Draft Environmental Impact Report (DEIR) was initiated in the fall of 1987. The DEIR concluded that the Fort Point Channel Underground Transitway using either trackless trolleys or dual mode busses with possible conversion to light rail technology was the designated alternative. Staged implementation opportunity, attraction of more riders, ability to serve other areas including Logan International Airport and the joint construction opportunity with the northbound Central Artery were the deciding factors for the underground option. Finalized in 1993 the Final Environmental Impact Statement/Final Environmental Impact Report further analyzed impacts of the underground option. After a positive outcome the design process started with alignment studies, construction feasibility study and operations analyses for Phase 1, starting at South Station and proceeding to the World Trade Center.

Initial alignments showed the Russia Wharf Segment of the Transitway passing through the ventilation building of the Central Artery project. Significant risk of vehicular accident due to sharp corners in the horizontal layout and conflicts with the ventilation building layout required a relocation of the twin travelway tunnel structure beneath the Russia Wharf Buildings. As shown in Figure 1, the tunnel structure traverses the Russia Wharf property entering at the southwest corner (Congress Street/Atlantic Avenue intersection) and passes northeasterly to the Boston Edison parcel. The Russia Wharf complex consists of three buildings, the Russia, Graphic Arts and Tufts Building (Figure 2), of which the first two are affected by the tunnel construction. The buildings are founded on timber piles.

Figure 2. Tufts Building at Russia Wharf complex.

During the preliminary design phase a cut and cover tunnel with underpinning of the Russia and Graphic Arts Buildings was developed which required partial demolition of the buildings in order to install the support of excavation and underpinning. A Value Engineering Review as required by the Federal Transit Administration (FTA) which was carried out after the 30% design completion surfaced that the proposed cut and cover scheme was the most expensive option and recommended the demolition of the buildings to build the tunnel. This proposal received great resistance of the Massachusetts Historical Commission (MHC) which encouraged the MBTA in March 1996 to develop an Analysis of Alternatives. Following the requirement to reduce the extent of demolition alternative construction schemes were developed.

Option A: Open Cut and Cover

This modified cut and cover alternative eliminated long underpinning girders by introducing post-tensioned concrete. Support of excavation was established by placing low headroom minipiles in close spacing. These measures only reduced but did not eliminate demolition of the lower floors of the buildings and furthermore, cost and schedule considerations did not satisfy project needs.

Option B: Shield Tunnel with Liner Plates

To accommodate both, in- and outbound lanes, the circular shield tunnel with steel liner plates had the largest cross section of the proposed methods. Excavation was foreseen by hand mining after the underpinning of the foundations would be in place. However, difficulties with numerous timber foundation piles and the high cost of a shield for the short length of tunnel as well as unresolved alignment details to adjacent tunnel sections were reasons finally not to proceed with the mechanized shield method.

Option C: Elliptical Pipe Arch with Micro Tunneling

Before advancing with tunnel excavation an elliptical pipe arch is installed at the crown of the tunnel cross section. Pipes would be excavated with micro tunneling techniques. Beneath the completed support arch the tunnel would be excavated and supported by either shotcrete or steel ribs and lagging. Difficulties with feasibility and accuracy of micro tunneling through the `forest' of foundation piles, high cost and low advance rates were not competitive with other methods proposed.

Option D: Rectangular Jacked Box

Jacking a pre-cast reinforced concrete tunnel box of the proposed size through the ground requires high jacking fore es. Underpinning of the. foundations and additional face support with either grouting or ground freezing would be installed prior to excavation. Cost, schedule, excavation through the timber pile foundations, but most of all the very limited and restricted site working zone made this option unfeasible.

The above alternatives did not provide the level of feasibility and economy required to realize the project. A more viable option was sought after and, based on precedent examples ground freezing in combination with shotcrete support tunneling techniques was introduced in the discussion resulting in the conceptualization of Option E. Option B and E were then made subject of a more detailed feasibility study.

3 IMPLEMENTATION OF INNOVATIVE TECHNOLOGY

In general, it may be said that the driving force behind innovation is a specific need. At the Russia Wharf buildings it was the need to build MBTA's South Boston Piers Transitway underneath an occupied office building through difficult ground and foundation conditions (timber piles) at economic cost while preferably maintaining the buildings undisturbed during construction and preserve its historic value. A need, that even under complex urban tunneling conditions may be classified as complex and very difficult to realize. None of the four options proposed was capable of optimizing the individual requirements involved.

Around the time of alternative selection a relatively little known tunneling project was on-going near the city of Salzburg, Austria. It involved shotcrete supported tunneling through soft, alluvial deposits with an increased difficulty consisting of timber pile obstructions frequently present in the excavation face. Dr. G. Sauer of DSC, Herndon, VA acquainted MBTA and their prime consultants led by Frederic R. Harris, Inc., Boston (FRH) with the technology used at that particular project and suggested the use of shotcrete support for tunneling beneath the Russia Wharf buildings. Although NATM tunneling in softground tunnels has not been done to date in Boston's underground, its application appeared feasible considering the many softground applications world wide. In order to accomplish cutting of the loaded timber piles, integrating those into and subsequently imposing their load onto the tunnel shotcrete lining however, a form of temporary support for the building was required. With the suggestion to include groundfreezing for temporary building support and tunnel roof pre-support during tunneling and meeting the owner's specific need the MBTA and FRH agreed to consider this new option.

Groundfreezing is a known engineering method for tunneling and shaft sinking in difficult ground conditions (Jessberger, 1981) but often considered the 'last resort' at high costs. The groundfreezing method in combination with NATM tunneling was known from several national and international but in particular European projects where it had been successfully used for temporary building support in association with tunneling underneath. The proposed combination of integrating the loaded timber pile foundation support into a frozen soil body for temporary underpinning, cutting off the timber piles during tunneling and rest them on tunnel lining for permanent support, once the soil body is thawed, whereas the tunnel tube would act as a largescale, concrete strip foundation, constituted a unique engineering concept. For a more thorough evaluation of this concept the MBTA agreed to initiate a feasibility study into this concept with engineering efforts led by FRH with DSC as tunneling specialty consultant.

The acceptance of sound engineering principles backed by a coarse review of case histories by the MBTA and the project team constituted the first, groundbreaking step towards considering the innovative approach. The implementation from this important, first agreement in principle by the owner and his engineering team to preparation of contract documents was a muiti-phase approach involving the following steps:

Feasibility Study:

During the course of the feasibility study over 50 groundfreezing case histories were reviewed. From these a total of 25 was selected to represent relevant conditions in terms of tunnel size, ground conditions, building support, ground freezing approach chosen, and ground freezing techniques applied. In particular this last item was of importance in view of ground conditions, installation of freeze pipes considering the presence of a dense timber pile pattern and the need to minimize freezing related ground deformations (freeze-thaw related heave and settlements). To address groundfreezing concepts and engineering the specialty consulting firm of Prof. Jessberger and Partner (J+P), Bochum, Germany was brought onto the team. Their previous work was associated with several of the case histories studied and groundfreezing expertise developed. Among others the `intermittent freezing.' a technique that uses cyclic freezing/non-freezing periods after the initial build-up of the frozen soil body to minimize ice segregation and associated heave was of interest to the project.

Site Visits:

Site visits were conducted to a selected number of sites in Europe; Germany, Switzerland, Austria and the UK and formed a part of the feasibility study. MBTA and project team representatives discussed Russia Wharf Tunneling issues as related to use of the new alternative with owner, contractor, and engineer representatives of the individual projects visited. This included issues of technical and contractual nature: type and method of freeze pipe installation, heave and settlement behavior, construction contract form and level of design detail required, contractor and specialty contractor pre-qualification requirements, abutter and tenant concerns during construction to name the most relevant ones. The experience and knowledge drawn from the site visits combined with the engineering approach taken for the tunneling at Russia Wharf were collected in the feasibility study report (Paragraph 4, Feasibility Study).

Peer Review Board:

A peer review board consisting of nationally and internationally recognized experts representing the geotechnical, structural and in particular groundfreezing disciplines as well as the Boston heavy underground construction industry was invited to formally comment on the outcome of the feasibility study. This Review Board approved the recommendations made in the feasibility study provided further refinements would be implemented during a final design. These included an engineered settlement/heave compensation system based on a jacking approach, recommendation that the vertical freeze pipe installation be used, limitation of the freeze depth to only the upper boundary of the clay stratum and use of additional minipiles on as required basis to aid in building foundation support.

Concluding the feasibility study phase FRH issued the Russia Wharf Study - Selected Construction Alternatives in November 1996 recommending the use of the shotcrete support method with ground freezing for the tunneling at Russia Wharf.

Abutters:

The Russia Wharf Tunnels will be constructed in conjunction with the Central Artery / Tunnel (CAIT) project which involves construction of slurry wall supported tunnels and ventilation buildings in direct vicinity of the Russia Wharf building complex. Ground freezing will be carried out in direct vicinity to slurry wall supports. Both CA/T and MBTA tunnel construction will have an impact on building deformations which in their sum have to be kept to predetermined limits. An agreement was established that CA/T and MBTA will exchange and jointly evaluate construction related deformation data. Building deformation and construction scheduling and its extent of impact were of concern to the building owner. In general both the CANT and building owners and their engineering and legal representatives were involved early on for consideration of their criteria and coordination issues.

Design Development:

During design development a formal contractor outreach program was initiated by the design team. This outreach program had two main purposes. First, it aimed at identifying specialty contractors who would be qualified to perform the work. Second, the contracting community would be kept informed about the progress of the project as it evolved from a conceptual design level through to bid documents. Only pre-qualified contractors were invited to participate in these formal outreach sessions with the opportunity to comment on design specifics and making suggestions on construction methods proposed by the designer.

4 FEASIBILITY STUDY

Although the feasibility study combined information gathered from case histories and lessons learned from the site visits its core was the development of conceptual freezing and tunneling means and methods under the specific geotechnical and structural restrictions of the Russia Wharf Segment.

4.1 Means and Methods for Tunnel Construction

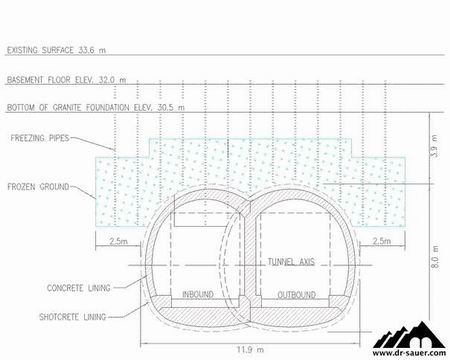

To meet the alignment constraints entailed by the corridor defined in plan (right of way) and the limited clearance available between the tunnel roof and the Russia Building granite block foundations, two tunnel arrangement alternatives were developed: a single and a binocular tunnel cross section (Figure 3). These two arrangements were investigated as to their impact on ground freezing, tunnel excavation and support sequence, construction staging, access and adjacent buildings.

The single tunnel comprised one tunnel to encompass both the Transitway Inbound and Outbound lanes. The supporting ground freezing arch spans across the entire section from sidewall to sidewall. For the excavation and primary shotcrete lining installation excavation with sub-headings was proposed.

The Binocular Tunnel consists of two single tunnels that partially overlap each other., Each tunnel was to be driven separately. The final concrete lining was to be installed after completion of the excavation and support of the first tunnel, followed by the construction of the second tunnel (Figure 6). A common concrete center wall would provide support in the area where both single tunnels overlap.

Advantages and Disadvantages of both methods were assessed and evaluated to provide comprehensive information to the MBTA for the decision making process that had to follow after the Feasibility Study for the final decision.

4.2 Means and Methods for Underpinning by Ground Freezing

Primarily two European projects were supporting the idea to use ground freezing for building and ground support during tunneling: At the Oberbilker Markt (Metro Dusseldorf, Germany; J+P) and Vivenotgasse (Metro Vienna, Austria; Deix and Braun,1988) sensitive buildings had to be underpinned with frozen ground to facilitate tunnel construction. In both cases tunneling was carried out with minimum clearance between the tunnel roof and the building foundations whereas the buildings remained in operation during the ground freezing and tunnel construction process. Though using different freezing configurations, both projects were successful and yielded valuable information for the development of the concepts and the decision finding process at Russia Wharf.

Referring to the case history of the Milchbuck Tunnel (Zurich, Switzerland; Schmid, L.1981), the intermittent freezing method was proposed to obviate undue heave during the ground freezing period.

In order to establish a frozen soil body, a cooling agent has to be circulated through freezing pipes and a refrigerating plant to extract the heat from the ground. The numerous examples for ground freezing demonstrated that two primary freezing pipe arrangements were used: a. Vertical Freezing Pipes and b. Horizontal Freezing Pipes.

The vertical freeze pipes are installed from the surface in a pattern and stepped to follow the shape of the tunnel, whereas the horizontally installed freeze pipes are arranged arch-like above the tunnel roof and haunches similar to canopy-type, pre-support grouting pipes (Figure 4).

Figure 4. Vertical Freeze Pipes around Binocular Tunnel Roof Perimeter.

Both systems were developed to an outline level and a detailed discussion section described advantages and disadvantages of each arrangement and their evaluation against the project specific requirements and constraints resulting in the recommendation for the employment of vertical freeze pipes.

4.3 Permanent Building Under pinning

It was the declared purpose of the proposed construction methods to facilitate the tunnel construction beneath the Russia Wharf buildings with minimum disruption to the building tenants while providing the maximum safety for the tunnel and buildings during and after the construction period. Therefore, it was proposed to utilize the tunnels for a permanent underpinning system where the tunnels intersect the complex wood pile foundations of the buildings. The cut piles would rest on the tunnel shotcrete lining (Figure 5).

5 DETAILED DESIGN

Following the decision by the MBTA to pursue the ground freezing und tunnel construction methods proposed in the feasibility study, the concepts delineated in the study were adopted and further developed during the detailed design. To meet the, space, alignment and settlement constraints, the Binocular Tunnel arrangement was selected for the tunnel construction. The top heading, bench/invert excavation and support sequence was adopted for the construction of the single tunnels.

For the Graphic Arts Building, the concept of permanent building underpinning using the existing wood pile foundations resting on the tunnel shotcrete lining was further detailed by designing pile shoes in which the cut piles will be held in place and the building loads will be supported by the tunnel structure (Figures 5 and 6). The structure will be waterproofed with a closed, sectioned membrane waterproofing system. Mueser Rutledge Consulting Engineers, New York (MRCE), who was engaged for the ground freezing design during the detailed design development used groundfreezing as the sole means for temporary support during tunnel operation for the Graphic Arts Building and combined it with permanent underpinning measures under the Russia Building.

Due to the presence of foundation remainders of an abandoned power station in the area between the work access and the Graphic Arts Building, ground freezing will be used for groundwater cut off and tunneling will take place under the pre-support of spiles installed in the tunnel roof area.

To assess the complex ground and structure behavior during and after the tunnel construction, three-dimensional Finite Element analyses were carried out. The calculation model covered the entire tunnel section underneath the Graphic Arts (Figure 7) and Russia Building. The computations underneath the Graphic Arts building indicate the compatibility between freezing approach chosen, tunnel construction methods proposed and building deformation limits established. A thorough monitoring system of tunnel linings, stresses at pile shoes (cut-off piles), stresses in the linings, as well as building and foundation deformations will be in place to verify construction performance.

6 REFERENCES

Deix, F., Braun, B. 1988. Vienna Subway Construction - use of brine freezing in combination with shotcrete support method under compressed air. Proceedings of the 5`' Int. Symposium on Ground Freezing, Jones&Holder (eds), Balkema, p.321 - 330.

Feasibility Study. Shotcrete Support Method with Groundfreezing at MBTA South Boston Piers Transitway Section 0003A. Prepared for MBTA on behalf of Frederic R. Harris, Inc. by Dr. G. Sauer Corporation. 27 September 1996.

Fortner, B. Through Frozen Ground. Civil Engineering. March 1999, pp. 34-39.

Jessberger, H. L. 1982. A State-of-the-Art Report. Ground Freezing: Mechanical Properties, Processes and Design, In Ground Freezing 1980: Developments in Geotechnical Engineering. ed. P.E. Frivik, N. Janbu, R. Saetersdal, and L.I. Finboru, Amsterdam: Elsevier, Vol. 28, pp. 5-30.

Jessberger & Partner: Project brief in Company Presentation

Massachusetts Bay Transportation Authority. South Boston Piers/Fort Point Channel Area Transit Feasibility Study. Prepared by URS Corporation. June 1987.

Massachusetts Bay Transportation Authority. South Boston Piers/Fort Point Channel Transit Alternatives Draft Environmental Impact Report. Prepared by URS Consultants, Inc. September 1989.

Massachusetts Bay Transportation Authority, Federal Transit Administration. Final Environmental Impact Statement/Final Environmental Impact Report. December 1993.

Russia Wharf Study, Selected Construction Alternatives, South Boston Piers Transitway Project, MBTA Contract No. CCO3A prepared for MBTA by Frederic R. Harris, Inc., November 6, 1999.

Schmid, L. 1981. Milchbuck Tunnel: Application of the freezing method to drive a three lane highway tunnel close to the surface. Proceedings of 5`' North American Rapid Excavation and Tunneling Conference, San Francisco. May 1981, Vol.1, pp. 427-445.