You are here

Flexible Approaches for Urban Tunneling

Flexible Approaches for Urban Tunneling

ASCE 2000

ASCE Conference, March 2000

ABSTRACT

The ever increasing use of urban space above ground leads in turn to an increased consideration of underground space. While this is primarily true for transportation projects involving rail based mass transit and highway arteries, other uses for the underground gain popularity and involve research parks and parking caverns among others. Because of the densely built urban settings, restrictions for tunneling below become tighter and the challenges greater. Access or entry and egress points to underground transportation, facilities are dictated by local or regional transportation needs and therefore dictate horizontal alignments. The call for efficient passenger circulation in mass transit and the need for interchange with at grade roadways often dictate the vertical alignment with the tendency towards shallow tunnel structures. With a relatively strong argument for a preferred vertical and horizontal location, less considerations can be given to a preferred location from a geohydrological point of view and the tunnel design and construction has to cope with whatever the ground conditions may be. On the other hand, the tunneling method chosen has to be sensitive to the integrity of surface and subsurface structures and to everyday routines of the urban life.

OVERVIEW

The ever increasing use of urban space above ground leads in turn to an increased consideration of underground space. While this is primarily true for transportation projects involving rail based mass transit and highway arteries, other uses for the underground gain popularity and involve research parks and parking caverns among others. Because of the densely built urban settings, restrictions for tunneling below become tighter and the challenges greater. Access or entry and egress points to underground transportation, facilities are dictated by local or regional transportation needs and therefore dictate horizontal alignments. The call for efficient passenger circulation in mass transit and the need for interchange with at grade roadways often dictate the vertical alignment with the tendency towards shallow tunnel structures. With a relatively strong argument for a preferred vertical and horizontal location, less considerations can be given to a preferred location from a geohydrological point of view and the tunnel design and construction has to cope with whatever the ground conditions may be. On the other hand, the tunneling method chosen has to be sensitive to the integrity of surface and subsurface structures and to everyday routines of the urban life.

Tunnel boring machines, cut-and-cover techniques and variations of the hand mining method were and still are the main construction techniques being used for urban tunneling. With the introduction of shotcrete as initial support implemented within a framework of generally accepted principles of ground behavior, a new technique has been developed allowing for increased flexibility in approaching urban tunneling tasks. Nowadays, this technique competes well with conventionally driven line tunnels in soft ground and can not be surpassed by other methods for the construction of stations, complex geometries such as bifurcations, large cross sections and other, complicated underground openings. Since its introduction for urban soft ground tunneling on the Frankfurt, Germany metro in the late 60's and early 70's, enhancements in the field of ground improvement have provided an even greater range of applications. The technique has been implemented in combination with grouting and ground freezing methods to enable tunneling underneath buildings and with compensation grouting to prevent otherwise settlement induced damage to surface and subsurface structures. In recent years, the method has seen application for the rehabilitation of brick lined tunnels and derivatives of the technique are used as alternatives to cut-and-cover construction. The technique's dual lining character (initial shotcrete and cast-in-place concrete inner lining) has favored the application of a waterproofing technique based on a continuous, flexible membrane sheet, which provides a completely dry underground space.

Based on the involvement in numerous mass transit projects in major cities in the US and abroad including Europe, Asia and South America, case histories have been selected to demonstrate the flexibility of shotcrete as initial support for construction of complex schemas and indifficult ground conditions.

These case histories include new tunnel construction as well as rehabilitation of old existing tunnels. A brief historic overview of waterproofing using flexible membranes from mined tunnel construction to cut-and-cover structures is laid out using case histories on selected projects, presenting dry underground spaces.

HAND MINING

This synonym for excavation by hand (spades, pickaxe, etc.) using ribs and lagging as initial support has been advanced in the second half of the twentieth century with the introduction of shotcrete as initial support and advanced hydraulic excavators and road headers for excavation. Although tunnel progress was substantially improved, it was the free space at the excavation face which made this combination so attractive, flexible and adaptable. There is no massive machinery or woodwork support which would hinder access to the excavation face. Where unforeseen conditions appear, immediate measures can be taken to remediate the situation (Sauer et ai., 1999).

Shotcrete (gunite) was invented and patented at the beginning, of the twentieth century in Allentown PA, 1912, and was used for the first time in 1954 to stabilize and support squeezing ground in an eight (8) meter diameter diversion tunnel for an Austrian power plant (Mueller 1978, Sauer 1988). After a number of successful applications for water-, rail- and road tunnel projects, this method was adopted for the first time in urban areas in soft ground for a section of the Frankfurt Subway (Krimmer, Sauer 1985). This construction took place in Frankfurt clay in 1968. Because of its obvious flexibility, economy and safe performance, more than two thirds of Germany's mined urban mass transit tunneling sections in more than 10 major cities were carried out using this method by the mid 1970's. These tunnels were constructed in a variety of soft ground conditions, including formations such as clay, silty clay and silts and soft marl.

For the performance of the work using shotcrete as initial support, only a few highly skilled miners and supervisors are required, while the majority of the mining crew can consist of locally recruited mining workforce. No major pre-investment is necessary and the excavation can start immediately after contract award. Its big disadvantage, the slower excavation rate, can be overcome by increasing the number of excavation faces from additional shafts or adits (Heflin et al. 1997).

The NATM (New Austrian Tunneling Method) is said to be an observational method (Peck 1969). Therefore, monitoring (in-situ measurements) of ground and opening deformations and stress development on and in the initial lining (shotcrete) is recommended. Any remedial work, caused by violation of material specification, misalignment or other construction errors, must be carefully designed and follow the same step-by-step approach as adopted for the main design work.

Ground Improvement and Additional Support

There is a wide variety of ground improvement techniques available today. These techniques are equally applicable to underground construction methods and range from dewatering to grouting and ground freezing measures to name the most common ones. The shotcrete support method uses additional support measures that are applied from within the tunnel to enhance stand-up characteristics of the ground and to control deformations.These additional support measures are summarized in Figure1.

Figure1. Additional Support used with NATM.

FLEXIBLE APPROACHES FOR URBAN TUNNELING - NEW TUNNEL CONSTRUCTION AND REHABILITATION

The following representative urban tunneling schemes have been selected to demonstrate the shotcrete support method's performance in urban settings in soft rock.

DART Section NC-1B: CityPlace Underground Station

Dallas Area Rapid Transit (DART) adopted the NATM for the only underground station on its 20mile Light Rail Starter System. CityPlace Station is the centerpiece of Section NC-113 which also involves 3 miles of bored twin tunnels. Significant cost advantages over alternative options led DART to adopt shotcrete as initial support. The underground station is located just north of the city, underneath the US 75 North Central Expressway and links directly into the basement of the high-rise CityPlace office complex (Figure 2).

Austin Chalk is a competent, relatively dry limestone which has proven to be a highly suitable tunneling medium. The medium to soft rock has an average unconfined compressive strength of 10-15 MPa and comprises thin, well cemented horizontal layers of limestone deposits from the Cretaceous Age. In such ground, section NC-1B including construction of CityPlace Station was estimated at $122.4 million, substantially lower than the conventional underground CityPlace estimate of $218 million which proved to be less expensive than the estimated $220 million combined highway/metro option (Ugarte et al. 1996).

Figure 2. Isometric View of CityPlace Station and Geotechnical Instrumentation.

The savings over more traditional underground design excavations are accrued principally through the different material requirements and time savings devices incorporated in the shotcrete application approach. Where steel arches and thick walled, heavily reinforced concrete linings might have been used in a more traditional design, the NATM approach in Dallas is based on more spacious openings in the stations and more cost effective use of materials for shotcrete lining, rock support and cast-inplace concrete inner lining (Figures 3, 4). Plastic waterproofing membrane and drainage system in the station and public access structures is another cost effective element readily identified with the NATM concept and one which is known to provide significant long term maintenance and operating savings.

Figure 3. South End of Platform.

Figure 4. South End Cross Adit and Station.

WMATA Section F6-B: Optimization of Tunnel Pre-Support

Tunneling started in October 1996 and the "hole through" inthe inbound tunnel was made in September 1997. Contract specification called for a number of pre-support measures to stabilize the tunnel crown in areas where saturated sand layers were known to occur and in adjacent sections where the thickness, extent and stability of clays referred to as P1 material over the tunnel were uncertain (Figure 6).

Figure 5. F6b Tunnel Regular Cross Section.

These measures included pre-support grouting using directional drilling, grouted pipe spiling, and rebar spiling, in combination with dewatering in advance of the face. These measures were required to increase the stand up time and cut off groundwater. Tunneling of the outbound tunnel was achieved with only occasional pre-support measures through the Cretaceous clays and only minor adjustments to the observed conditions. Pre-support chemical grouting of the northernmost 70 m, where a saturated sand layer was mapped in the crown, peimitted advance through this area as specified.

Figure 6. Longitudinal Section Outbound Tunnel.

However, during mining of the inbound tunnel, separated by only a 6 m pillar, interception of 4 unmapped sand lenses in the crown resulted in unexpected groundwater inflow and work stoppages. With chemical grout injection primarily from inside the tunnel and installation of drain pipes ahead of the face (Figure 7), the contractor was able to resume safe mining below a hydrostatic pressure of up to 8 m, successfully completing work within schedule (Gall et al., 1998).

Figure 7. Grouting from within the Face.

MBTA Contract 0003 A: Frozen Ground for Building Support

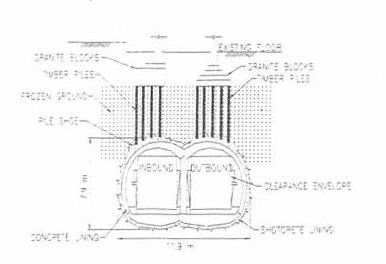

The Russia Wharf Segment of the South Boston Piers Transits ay project crosses underneath the Russia Wharf properties. These properties comprise the Russia Building, Tufts Building and Graphic Arts Building, where the Tufts Building is located outside the tunnel alignment (Figure 8). These historical buildings were built approximately 120 years ago and are founded on timber piles. The building columns rest on pile caps, consisting of granite blocks that are not interconnected. The clearance between the new transit tunnel roof and the pile caps varies from approximately 4.2 m to 1.8 m. The tunnels for the new transitway will accommodate bus traffic and, at a later stage, possibly light railway traffic.

Figure 8. MTBA Section CC03A at Russia Wharf - Plan View.

The original design for the tunnel construction foresaw a box tunnel constructed within an open cut. The buildings which were located above the tunnels had to be evacuated, underpinned and the lower floors had to be stripped from all walls, floors and partitions to facilitate access for the excavation and support operation. An alternative method :vas developed that allows the construction of the new transitway tunnels while Russia Building and Graphic Arts Building will remain in use as office buildings during the construction period (Fortner, 1999). Only the basement floor, that is currently used as a parking garage will be occupied by construction facilities and equipment. This alternative method employs ground freezing to improve the ground around the tunnel roof area (fill material) such that the new tunnel can be mined essentially without disruption of surface and subsurface structures. For the initial tunnel support, reinforced shotcrete will be utilized. The timber foundation piles of the buildings will rest in special pile shoes on the tunnel lining (Figure 9). For permanent waterproofing and tunnel lining, a membrane waterproofing system and reinforced cast-in-place concrete lining will be installed.

Figure 9. Cross Section showing permanent Underpinning of Piles.

Port Authority of Allegheny County, Pittsburgh, PA: Reconstruction of the Berry Street Tunnel

The brick lined Bevy Street Tunnel in Pittsburgh, PA, was built in 1865 (Garrett, 1997). The tunnel refurbishment began in April 1996 and included the widening of approximately 710 m of mined tunnel and approximately 160 m of a cut-and-cover section at the north-east end of the tunnel (Gall et al., 1998). The main part of the tunnel was widened using steel fiber reinforced shotcrete for initial support (Figure 10a). The cut-and-cover section at the north east end of the project was widened partially using mining techniques as far as practical. 'Where the backfill cover above the tunnel became too shallow, the method was changed to cut-and-cover techniques and a shotcrete canopy was installed in the open cut. After installation of a waterproofing system, the unreinforced cast-in-place concrete lining was installed (Figure 10 b). Tunnel refurbishment work was completed in August 1997. The success of the project was a consequence of the flexible design and re-construction approach selected. Modern support measures required for the expected ground conditions were thoroughly designed and prepared providing various tools to be utilized in varying combinations and adaptions to overcome the problems encountered.

Figure 10a. Shotcrete Canopy Installation under Voids.

Figure 10b. Final Tunnel Lining.

London Underground: Brunel's Thames Tunnel

Brunel's Thames Tunnel is an approximately 400 m long brick lined tunnel and was built using a rectangular shield between 182 and 1843. The tunnel connects the Thames river north bank with the south bank in London, UK. Two tunnels with horseshoe profiles were constructed within the bore. The twin tunnels are connected with a series of brick lined arches at approximately 5.5 m. The prime objectives of the rehabilitation were: Strengthening of the tunnel's structural support to ensure its integrity for the next hundred years including flood mitigation; additional clearance for an improved track alignment and larger rolling stock; modernization of electrical and safety equipment. British Heritage, the UK Authority for preservation of historic buildings, requested the preservation of all arches connecting the twin tunnels, a complex back-of-lining drainage and architectural features in the final lining similar to those generated by Brunel (Roach, 1998).

To observe all these project aims and to ensure safety during the rehabilitation operation, a series of excavation and support techniques were adopted. An `excavation' sequence was developed that allowed sections with limited lengths and depots for brick lining trimming according to the assessed brick lining conditions and thicknesses. Temporary steel support frames and a comprehensive monitoring system were employed to ensure safety during the intermediate construction stages. Installation of the waterproofing/drainage system and the reinforced concrete or shotcrete final lining followed brickwork trimming in each individual trimming section. In March 1997, Brunel's Thames Tunnel was re-opened to the public.

Figure 11. Brunel's Thames Tunnel before and after Refurbishment.

WATERPROOFING

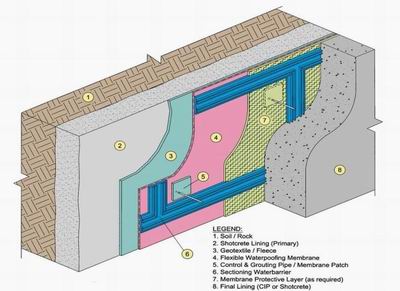

Due to their success, flexible membranes are now being utilized for the waterproofing of underground structures in general. Concepts of waterproofing for mined tunnels have been adapted to meet the challenges of cut-and-cover construction methods including soldier piles and lagging, slurry walls, sheet piles and others (Mergelsberg et al., 1996). Similarly, flexible membranes are being used more and more on rehabilitation projects of old, leaking tunnels.

Operators of new and refurbished underground systems such as metros, road and utility tunnels, and other subsurface structures such as libraries and parking garages are enjoying significantly reduced operation and maintenance costs as a consequence of dry underground space.

A system sketch for a typical waterproofing using flexible, continuous membranes is shown in Figure 12. This figure also depicts an enhancement of the system by the so called `sectioning' for controlled repair by grouting. The waterproofing is applied in either the 'open' or the 'closed' system. The closed system allows the watertable to raise over the structure. The open system in contrast uses sidewall drains at invert elevation for permanent drainage of groundwater (ground watertable below invert).

Figure 12. Waterproofing System and Sectioning.

CONCLUSION

With the increased amount of restrictions and complexity imposed on underground construction in urban areas, flexibility in construction approaches is sought. For the construction of short underground bores, complex geometries, cross-over chambers, escalator tunnels, bifurcations and other auxiliary space, use of shotcrete as initial support has proven to provide this flexibility at economical costs. It can be used for rehabilitation and reconstruction of aging structures as well. A combined use of ground improvement techniques allows the application of the sequential support techniques with shotcrete as initial support in virtually and kind of ground conditions provided an experienced design, skillful construction and responsible and experienced supervision is provided (Terzaghi, 1958 and 1998).

REFERENCES

Dressler, J. (1990): Design and construction of a shallow underground parking cavern in soft ground. Proceedings Vol. 1, International ,Symposium on Unique Underground Structures `90, Denver, Colorado, USA, Chapter 17, 1-17

Fortner, B. (1999): Through Frozen Ground. Civil Engineering, (arch 1999, Vol, 68, No 10, 16 Gall, V., Zeidler, K., Predis, T., Walter, J. (1998): Rehabilitation Concepts for brick lined tunnels in urban areas. Proceedings, World Tunnel Congress `98 on Tunnels and Metropolises, Sao Paulo, Brazil, pp. 539-546

Gall, V. , Zeidler, K., Meyers Bohlke, B., Leonard, A. (1998): Optimization of Tunnel pre-support - Softground NATM at Washington, D.C. 'Metro's Section F6b. Proceedings, North American Tunneling `98, Vol, 1, Newport Beach, CA, USA, 21-25

Garrett, R. (1997): Pittsburgh Berry StreetRebuild. North American Tunneling, June 1997 Issue Heflin, L. H. , Marquardt, J. M., Yen, J. H. N. (1997): Eight Heading Rock NATM. Proceedings, RETC, Las Vegas, 1997, Chapter 38, 625-630

Krimmer, H., Sauer, G. (1985): Die Neue Österreichische Tunnelbauweise im U-Bahnbau Rückblick und Ausblick. Österreichische Gesellschaft fir Geomechanik, Felsbau 3, Nr. 3

Mergelsberg, W., Gall V., Sauer, G. (1996): Achieving dry Cut-and-Cover Stations - A membrane based waterproofing system for underground structures. Proceedings, North American Tunneling `96, Vol, 1, Washington, DC, USA, 353-361

Mueller, L. (1978): Der Felsbau, dritter Band: Tunnelbau. Ferdinand Enke Verlag, Stuttgart,Germany, 945 p

Peck, R. B. (1969): Deep excavation and tunneling in soft ground. Proceedings 7''' International conference on soil Mechanics and foundation engineering; state of the art volume, Mexico City, Mexico, 225-90

Roach, M.,J. (1998): The strengthening of Brunel's Thames Tunnel. Instn. Civ.Engrs., Transp. 1998, 129, 106-115

Sauer, G. (1988): When an invention is something new: from practice to theory in tunneling. XXIIISirJulius Wernher Memorial Lecture, Institution of Mlining and Metallurgy, Tunneling `88 Symposium, London, UK, A94-A108

Sauer, G. (1990): Design concepts for large underground openings in soft ground using NATM. Proceedings Vol. 1, International Symposium on Unique Underground Structures `90, Denver, Colorado, USA, Chapter 1, 1-20

Sauer, G., Gall, V., Ziedler, K. (1999) Construction of Miscellaneous Undreground Structures for Subway Projects, ASCE Proceedings, April 1999, New York, NY, USA

Ugarte, E., Gall, V., Sauer, G. (1996): Instrumentation and its Implications - DART Section NC-113, City Place Station, Dallas, TX. Proceedings, North American Tunneling `96, Vol, 1, Washington, DC, USA, 503-512

Terzaghi, K. (1958, 1998): Consultants, Clients & Contractors. BSCE Journal 1/1958 (reprinted at Civil Engineering Practice Fall/Winter 1998), Boston, MA, USA, 46-54

Wind, H. (1991): Soil and Rock improvement in underground works - site organization of ground freezing, criteria and recommendations. ATTI Proceedings, Vol. II, March 1991, Milano, Italy Zeidler, K., Gall, V. (1999): Shotcrete lining design concepts for new and rehabilitated tunnels. Proceedings, United Engineering Foundation Conference 1999 Shotcrete for Underground Support, Sao Paulo, Brazil