You are here

Urban Tunnelling Consequences

World Tunneling March 1998

The political and physical environment of larger cities makes decisions on heavy construction projects not always as clear an issue as in rural areas. Urban tunnelling has to be considered not as three-dimensional, not even as four-dimensional including time, but as five-dimensional including politics.

The issues confronting urban tunnelling today are not "can the tunnel technically be done?" but rather "what are the advantages and disadvantages of adopting one tunnelling technique over another, and the consequences of this decision?".

Consequences concern public and political support for the project, its costs and source of funding; risk assessment of each technique bearing in mind the alignment and expected ground conditions; its impact on the regional tunnelling industry; and the political risks of budget and schedule overrun.

No longer do tunnelling engineers need to ask if building a tunnel in any type of ground is possible! The international tunnelling society knows that today's excavation methods and their support techniques such as TBM, pressurised shield, explosives, excavators, steel and concrete segments and shotcrete, barrel vaulting, doorframe slab method, horizontal and vertical-jet grouting, compensation grouting, ground freezing, compressed air, etc., make tunnelling technically viable under virtually any circumstances!

The questions that confront us concern the social and human element. What are we willing to pay to avoid unwanted environmental impacts in lieu of improving our infrastructure? The taxpayer is not always being made fully aware of all the possible options by the press, the politicians, the academics and some so-called experts!

URBAN TUNNELLING

From a social point of view, a bored tunnel for metro, road, utility or railway alignments through urban areas is generally the preferred option. Many projects around the world illustrate this point. One of the largest is the Central Artery highway project in Boston which is currently being built for the third time. From the surface, the highway was elevated in the 1950s, and is now going underground.

The 2km-long elevated structure is being lowered into a cut-and-cover box. The elevated structure will be underpinned and will remain fully operational while the enormous open cut trenches are excavated directly beneath.

This particular example raises two primary points. First is the growing awareness of the general public. Public authorities can no longer ignore the wishes of the people. Several projects are feeling the impact of well-organised and adequately-funded public opinion. Bored tunnels attract least resistance from the general public and effective lobby groups have successfully imposed longer sections of tunnel as well as new alignments on several current projects such as the new NBS highspeed rail lines in Germany, the Channel Tunnel Rail Link through Kent County in the UK and many bypasses to avoid sensitive rural environments and residential areas.

The people of Boston will no doubt appreciate the new underground freeway when complete, but how will they tolerate the impact of the open-cut earthworks in their city centre over a period of some 10 years? The Boston example opens the second point which is: was the method chosen at the time the correct one?

Bored tunnels have a historic reputation for being the most expensive and highest risk option. This myth must be dispelled. Tunnelling engineers must ensure that the tunnelling option is given equal opportunity of consideration at feasibility stages and that adequate cost and risk comparisons are presented. Only by examining all the possible alternatives can a client, representing the ultimate paymasters - the general public, come to informed decisions.

Evidence accumulated from the experience of building the Hannover-Wurzburg highspeed railway in Germany from the late 1970s until the early 1990s illustrates categorically that when analysed in the final out-turn accounts, there was very little difference in the actual cost of building the railway either grade, on embankments, on viaducts or in bored tunnels.

Inclusion of all costs such as planning permission, public enquiries, compulsory purchase of land for surface or subsurface work and access, compulsory compensation cost to achieve rights-of-way, design and construction costs, insurance costs, and the final account of delays, claims and solutions, provide little difference in out-turn costs between the different construction methods - and these were in rural locations. Comparison of the different techniques on this basis in an urban area might well place the bored tunnel option on the positive side of the final out-turn cost.

ALTERNATIVE DESIGN

One method of ensuring thorough examination of all the alternatives was promoted and used with positive effect by Mr Walter Mergelsberg, former Deputy General Manager of the Washington Metro Area Transit Authority (WMATA). "You cannot let an engineer make decisions on what affects his own pocket" is the Mergelsberg philosophy.

In a quite innovative development, WMATA included alternative designs in contract tender documents giving the contractor the opportunity to cost each option and put forward the arguments in support of their decision. The cost to the client of engaging different consultants to prepare the alternative tender designs (to about 60% of final design) was returned many times over. Giving the construction options to the contractors increased the viability of the project (cost vs technical feasibility) and increased the competitiveness of the bid prices. Giving contractors the choice also allowed them to draw on their own experience and expertise and ensured concentrated attention to detail in the tendering process.

The final decision, of course, remained with the client. The point is illustrated by the B11b contract on the Washington DC Metro where, given the option of TBM or NATM, the client insisted eventually on the flexibility offered by NATM to work several headings at once and guarantee finish of excavation to meet the overall programme. Although both techniques were suitable, there was more risk of delays using the single heading TBM alternative. More privatisation and increased accountability through design alternatives in the tender documents, design-and-construct contracting, and privately financed concessions are perhaps the best methods of controlling project costs in the planning and design stages. For example, it was the private concession status of the Channel Tunnel project in the UK and France which adopted the effective use of NATM in golden Clay and chalk geology for all the access works on the UK side of the project. In this case it was Mr Ross MacKenzie as Director of Taylor Woodrow who insisted that TML (Trans-Manche Link) use the flexibility, speed of construction, and cost efficiency of the NATM technique for the access works, the Castle Hill approach tunnels, and later on the spectacular UK crossover chamber under the sea. Austrian consultant ILF was engaged to design and supervise the NATM works - with, it must be said, the silent consent of some knowledgeable colleagues in the UK consulting establishment.

Before that, British Gypsum, the owner of the Barrow-Soar gypsum mine in the UK, employed the NATM alternative with a high pressure waterproofing system to avoid long term pumping costs as the most efficient method of constructing two mine-access tunnel drifts. More recently in the UK, where protection of traditional methods has been fiercely defended, BAA, the privatised owner of Heathrow Airport in London, was persuaded first of all to undertake a NATM trial in the famous London Clay and then specify the method for the underground stations on its proposed Heathrow Express Rail Link.

The trial tunnel results not only persuaded BAA that NATM was the most cost effective of the options, it also persuaded designers working on the London's CrossRail project to make use of this flexible concept for its five underground stations on that project and convinced London Underground Ltd, owners of the Jubilee Line Extension (JLE) to accept more cost and technically efficient NATM alternatives for excavations at Waterloo and London Bridge.

The causes of the subsequent NATM collapse at Heathrow in 1994 and its ramifications are part of other consequential concerns.

PROJECT COSTS

In planning a new road or railway across an urban area, what is it that determines its cost? The obvious cost elements are evident. The cost of expropriating the necessary rights-of-way; compensation to those impacted; estimated cost of construction regardless of the method chosen; the overheads. Insurance and a contingency are also recognised budget costs.

But what of the less obvious costs? Those incurred through vested interests. Interference by politicians for political expediency, for example, to change route alignments or to accelerate construction schedules ahead of political elections. Some protect the home markets by excluding foreign competition, or resort to cancellation of projects in response to political pressure.

Again, there are many examples around the world. One of the more recent is the Toronto Subway where budgets cuts caused construction on one extension to be stopped in order to start and complete a second extension first.

Other hidden extras include the chance for public utilities to have services renewed under the umbrella of somebody else's budget, a situation which depends heavily on the choice of construction method between cut & cover and mined tunnels.

One historically proven political measure is fear! The promotion of a particularly-expensive scheme as the only feasible option by engendering an unreasonable fear against other more economic ones may publicly be smart, but does not help the economy, technology and the taxpayer. It takes particularly strong personalities in client organisations to protect the project from becoming a political football or to break the cosy relationships of the old boys' network and put their public accountability to the taxpayer at the top of their list of priorities.

INCENTIVE

Public work projects such as tunnels are let by politicians and civil servants, spending taxpayers money. But what are the incentives for them to promote cost efficiency? There appears to be very little for government employees to gain by going against the way things have always been done in the agency. There is little reward for showing initiative or accountability, and too few government employees in positions of power are willing to allow themselves to be persuaded. It can be extremely difficult to gain access to the client to promote alternatives to project designs.

In the United States, acceptance of the first major NATM contract to save significant costs on the B10 Wheaton Station contract on the Washington DC Metro was a significant achievement against fierce opposition.

Overcoming protectionism by the consulting engineering establishment to present an updated and less expansive option to the client is perhaps the first of many savings possible in the field of providing necessary infrastructure in urban areas. Again the examples are many. For instance a significantly less expensive, fully-waterproofed NATM alternative for the Saltash road tunnel in the UK in 1985 was rejected in favour of the more-expensive traditional methods of using heavy steel arches and timber lagging to support the excavation with heavily reinforced in-situ concrete of the final lining. The result, after less than 10 years, is a badly cracked and leaking tunnel in need of major rehabilitation, following a construction contract which escalated significantly due to various claims and change orders.

CONSTRUCTION COSTS

Risk assessment may be considered as an exercise which will indicate in favour of one method over another. It is designed to inspire confidence among clients that the decisions they are making are correct, or to at least heighten awareness of the risks associated with their decisions. It is often as a part of this exercise that tunnelling is dismissed. Bored tunnelling must be given fair representation, and NATM in soft ground has proven to be the most cost effective technique of excavation short tunnels; complex and variable cross-sections; and underground facilities such as metro stations, car parks or storage caverns. Cost comparisons in these cases favour shotcrete over most other support systems. In the hands of competent operatives this technique is intrinsically safer by way of the ability to respond more rapidly to the need for extra support.

RISK AND SAFETY

The risk associated with NATM however, as compared to other techniques in urban areas, is often perceives to be high. This is misleading. There is no evidence to support claims that there are more incidents of settlement damage or collapses or accidents with NATM than with shield-driven tunnels or open cut excavations. Internal research before starting NATM at Washington DC Metro highlighted the fact that there were frequent stability problems associated with open face shield driven chosen in favour of NATM, daylight collapses occurred at an average of 600 m intervals, not to mention intermediate downfalls at the face. Spectacular blow outs of pressurised TBMs and emergency evacuation of houses along badly constructed slurry walls have been reported throughout the industry. Similar events have been investigated for shields, TBMs, cut & cover methods where the applied construction volume of each method in comparable ground conditions in relation to each other, has to be considered as well.

But there are other risks involved in heavy construction which count even more for the client such as schedule, budget and political consequences.

DURABILITY AND MAINTENANCE

After a few years of operation these issues become more and more important. Maintenance costs in leaking tunnels are exceeding budget all over the place in urban areas, leading to reconstruction and major rehabilitation works. The application of positive waterproofing, as one of the major construction issues, has made more and more clients aware of its viability. The possibility of later requirements such as reconstruction, tunnel widening, and the construction of new parallel lines, bifurcations and additional stations should be considered before choosing the initial scheme and its construction method.

LEGAL AND CONTRACTUAL ASPECTS

Every major project needs effective and independent and, most of all, competent control.

Federal Highway projects in the US, for example, have to go through a value engineering process along the 20% design stage. It is again the client's responsibility to choose independent recognized experts for a peer review, or a board of consultants. Appointing a general consultant for major projects makes sense but has its downsides as well. However, an effective control has to be established. There have been attempts to control the designer by appointing a site supervisor, but this has not proven to be necessarily cost effective.

The bottom line of my experience is that the client has to maintain the option to involve in the supervision of the project whoever he feels is competent to achieve a good quality product. My personal conclusion is that it is more effective to invest the money in competent supervision rather than in competent lawyers!

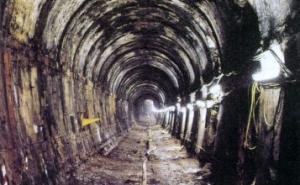

Rehabilitation of the 150 year old Thames Tunnel built by Mark Brunel from 1825 to 1843.

SUMMARY

Urban tunnelling is different. Money invested in heavy construction impacts upon other community interests and services and the politics are more complex than in rural areas. Urban tunnelling projects demand a client with the ability to select and combine competent specialised engineers to get the best quality product for the taxpayer.

"Quality is a virtue that starts in the mind. It is the ability to recognise interrelations, to evaluate, categorise and organise one's surroundings. It requires permanent and consequent thinking and staying alert. Quality is identification with one's own work. Demonstrate quality to produce quality!"

REFERENCES

- Kruckemeyer E. K.: Building it thrice. ITA Ass. At North America Tunnelling Conference, Washington DC, 1996.

- Geisler H., Möker H., Sauer G., Schrewe F.: Tunnelplanung der Deutschen Bundesbahn in erdfallgefährdetem Gebiet. Rock Mechanics, Suppl.12, 1982, pg.63-73.

- Culverwell R. D. in ass. with H.H.&P.:Proposed Channel Tunnel Rail Link at Sevenoaks Kent. Sevenoaks District Council. December 1989.

- Heflin H. L., Marquardt M. J., Yen H. N. J.: Eight Heading Rock NATM. Rapid Excavation and Tunnelling Conference, Las Vegas, Nevada, June 22-25, 1997.

- Biggart R. A., King J. R. J., Crighton S. G., Kirkland J. C.: The Channel Tunnel Project-the UK tunnels: a design and construction overview. IMM Tunneling London 1991, pg.125-142.

- Deacon G. W., Hughes F. J.: Application of NATM at Barrow-upon-Soar gypsum mine to construct two surface drifts. IMM Tunneling London1988, pg. 69-77.

- Deane A., Rulff J.: Heathrow Express NATM Trial Tunnel. World Tunnelling, June 1992, pg.242-246.

- Torp-Petersen G., Povey G. D.: Design development of the underground section of CrossRail. IMM Tunneling London 1997, pg.41-53.

- Murphy P., Moss J.: Jubilee Line at London Bridge. World Tunnelling, December 1993, pg.467-470.

- Project management - another layer of bureaucracy. Tunnels & Tunnelling International, December 1984,pg.34.

- Wallis S.: Sheppard Subway. World Tunnelling, September 1996, pg.N17.

- Martin D.: How the Austrians cracked the hard American nut with NATM. Tunnels & Tunnelling, December 1984, pg.23-26.

- Wallis S.: Caution the key to Cornish road tunnel. Tunnels & Tunnelling, July 1987, pg.33-34.

- Wallis S.: Tunnelling: theme and variations. World Highways/Routes du Monde, May-June 1995, pg.55-57.

- Blindow et al: unpublished work, 1979.

- Anderson J.: HSE reports on NATM safety. Tunnels & Tunnelling International, March 1997, pg.49-51.

- Garrett K.V.Jr., Sauer G.: Achieving a dry tunnel. Rapid Excavation and Tunneling Conference, New Orleans, Louisiana, June 14-18, 1987, Chapter 29, pg.461-478.