You are here

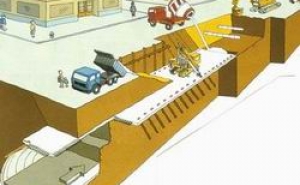

Doorframe Slab Method

A major problem in urban areas when attempting to reduce noise and pollution by providing shallow underground diversions to traffic, is the impact of long term construction on the daily routine of the city. Trenches which block central arteries for up to five years can ruin commercial businesses and totally ignore the concerns and objections of those most severely affected.

The Doorframe Slab Method is a semi cut-and-cover construction method for shallow tunnels. It substantially reduces the environmental impact to a matter of weeks. Opening of the trench, concreting of the roof slab, installation of the side wall pile support and backfilling of the trench to reinstate the surface are the only construction sequences seen by the public. The bulk of the work is carried out as a subsequent mining operation using the elements of the NATM.

This method is patented in Europe and the USA and has been offered as an alternative to avoid legal delays associated with suggestions of open cut methods for such projects.

Special Applications

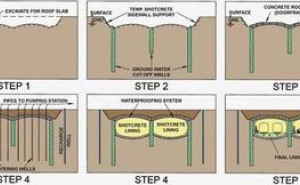

DFS in Water Saturated Sand Formations

The method also can be applied in water saturated sand formations. The major problem of constructing a shallow tunnel in these conditions is keeping the water out, keeping the face and invert stable while the structure is advanced within the slurry walls. An alternative to today's methods of jet grouting the bottom, chemical grouting between the slurry walls etc. is using a localized dewatering concept within watertight slurry walls. By means of immediately placing a watertight sprayed concrete invert step by step and as close as possible to the excavation face, water inflow is restricted to a minimum. A system has been developed as shown in the series of drawings below:

Please follow this link for an article describing the application of this method at a railroad crossing.