You are here

Caisson Method

The Caisson Method is an innovative tunneling technique for underwater tunneling, which is advantageous to conventional methods. It has minor environmental impact and permits the construction of a tunnel with minimum length and depth.

CONVENTIONAL UNDERWATER TUNNELING METHODS

SUBMERGED TUNNELS

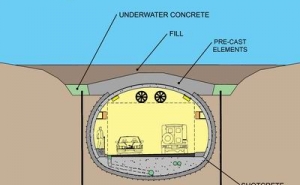

Prefabricated, 300 to 400 ft long tunnel segments constructed of steel or reinforced concrete are sunk into a pre-dredged trench and connected to the previously installed segments. The segments are then protected with backfill.

The major disadvantages of this method are the necessity of excavating a deep trench, setting up a costly facility for tunnel segment production and shipping the tunnel segments to the construction site. These activities disrupt marine traffic, pollute water and environment and take a substantial amount of time, thereby incurring high costs.

MINED TUNNELS

The tunnels are constructed using Mechanized Mining (Tunnel Boring Machine) or Hand Mining (NATM), supported by compressed air. A minimum overburden is required for structural stability during construction. Therefore, compared to submerged tunnels, the tunnel alignment must be lowered which in turn causes a greater tunnel length and potentially higher costs.

THE 'CAISSON METHOD'

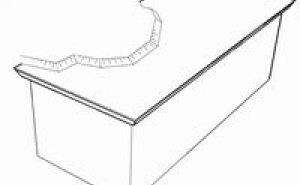

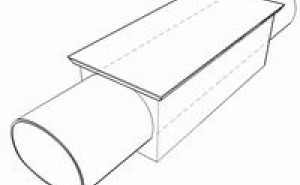

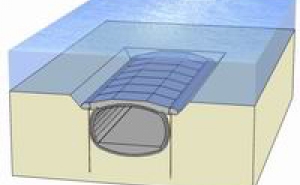

The concept is based on the creation of a 'caisson' by installing watertight lateral walls and a watertight roof slab (crown).

The roof slab usually consists of either cast-in-place or precast concrete elements. The tunnel is subsequently excavated beneath the roof slab by Hand Mining (NATM), with support of compressed air as required to control water inflow.

CONSTRUCTION STEPS

Step 1

Dredging of River/Harbour Bottom

Step 2

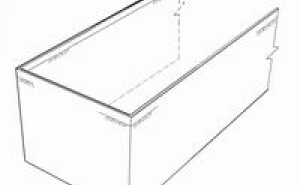

Installation of lateral walls

(driven sheet piles / slurry walls / jet grout walls / secant pile walls / thin diaphragma walls)

Step 3

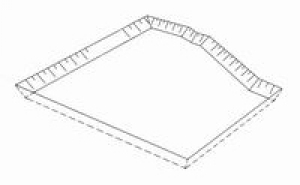

Installation of Roof Slab

(precast concrete / cast-in-place concrete)

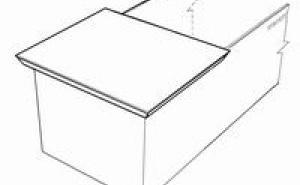

Step 4

Backfill

Step 5

Tunnel Excavation

ADVANTAGES OF THE CAISSON METHOD

Reduced Tunnel Length

This method requires a minimum clearance to be maintained between the top of the tunnel and the river bottom, which in turn allows the tunnel alignment to be raised, resulting with the shortest possible tunnel length.

Minimized Environmental Impact

The water turbidity is minimized because only minor dredging operations are required to install the lateral walls and the roof slab. After that, tunnel construction causes no disruption to environment and marine traffic anymore.

Adaptability to Ground Conditions

Hand-Mining is the most adaptable tunneling technique to handle all possible encountered ground conditions (foreseen and unforeseen) by using appropriate excavation sequences and various support measures.

Reduced Costs and Improved Schedule

Compared to conventional river crossing methods, this construction technique requires the least material to be handled/disposed; therefore the method promotes a shorter construction period, thus reduced costs.

SUMMARY

The Caisson Method is a cost effective, rapid and environmentally friendly tunneling method, highly adaptable to different ground conditions