You are here

Featured Projects - Beacon Hill Station

Project Overview

The Beacon Hill Tunnels and Station are part of the 14 mile initial segment of the Sound Transit Central Link Light Rail Line that will establish a high capacity commuter connection from downtown Seattle to Sea Tac then on South to Tacoma. The 4,300 foot running tunnel under Beacon Hill will be mined by Earth Pressure Balance Machine (EPB), while the deep mined Station will be constructed using slurry walls and the New Austrian Tunneling Method (NATM), referred to as Sequential Excavation Method (SEM) for this project.

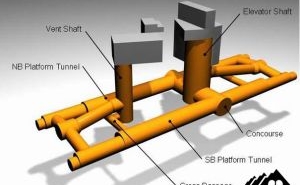

Beacon Hill Station Arrangement

From the surface Station Headhouse, a 181 ft deep, 46 ft inner diameter Main Shaft will be constructed that will house four high speed elevators, emergency staircases, ventilation shafts, mechanical and electrical equipment. A 26 ft inner diameter Ancillary Shaft will accommodate another set of emergency staircases and ventilation shafts. From the Main Shaft, the 41 ft wide Concourse Cross Adit will provide passenger and emergency access to the Platform Tunnels. These are 380 ft long by 32 ft wide and were designed to accommodate the platforms, artwork and architectural finishes, and the light rail tracks. Two Cross Adits will connect the Platform Tunnels, and Ventilation Tunnels will provide air flow in normal operation and for emergencies.

Design Responsibilities

The Hatch Mott McDonald / Jacobs (HMMJ) Joint Venture is the lead designer for the Beacon Hill Tunnels and Station, the architectural design is carried out by Otak. The Dr. G. Sauer Corporation services included the SEM design as a subconsultant for the Concourse Cross Adit, the Platform Tunnels and the Platform Cross Adits and Headhouse waterproofing systems.

Geology

The Puget Sound Area is characterized by a complex mixture of glacial and non-glacial soils that have been deposited, consolidated, eroded and reworked by multiple major glaciations during the Pleistocene Epoch and numerous seismic events. The exploration program showed that most of the Beacon Hill Station will be excavated within in glacial, overconsolidated, partly fractured or slickensided clays and tills. Intermittent sand and silt layers will be present with multiple perched groundwater horizons. The high variability of the geology in the area of the future station poses the main design challenge for design and construction.

SEM Design

Key elements for large SEM tunnels in soft ground:

- Ovoid cross sections with rounded inverts and domed excavation faces to prevent stress concentrations.

- Lining ring closure 1.5 times the tunnel diameter to prevent loosening of the surrounding ground and excess settlements.

- Timely installation of sealing shotcrete / flashcrete and the initial shotcrete lining to prevent deterioration and loosening of the soils.

- Subdivision of the excavation section into smaller drifts with adjustment of round lengths to be able to control and stabilize the tunnel excavation.

- Utilization of the appropriate ground support toolbox for face support, pre-support and ground improvement measures.

- Monitoring of the structure during construction to assure stability and verify design assumptions.

- The ability to make adjustments in the field to deal with actual ground conditions encountered.

- Experienced Construction Management, Site Supervision and Quality Control to ensure safety and efficiency.

SEM tunnel design has to take these factors into account and relies heavily on engineering judgment and experience from previous projects, but also on advanced Finite Element Modeling Tools to determine the appropriate excavation sequences and support measures.

The SEM Toolbox Approach:

To cope with the variable ground conditions, standard support measures (reinforced shotcrete, lattice girders) are augmented by additional support measures ("NATM Toolbox Items") on an as needed basis to ensure stability of the tunnel face and the surrounding ground. They include Pre Support Measures (Rebar Spiling, Grouted Pipe Spiling, Metal Sheets, Grouted Barrel Vault / Pipe Arch), Face Stabilization Measures (Face Stabilization Wedge, Pocket Excavation, Reduction of Round Length, Face Bolts), Ground Improvement Measures (Gravity and Vacuum Dewatering, Permeation Grouting, Fracture Grouting, Jet Grouting) and Annular Support (Additional Shotcrete, Soil Nails, Temporary Invert).

Tunnel Design

The cross section of the Station Tunnels were developed according to architectural requirements, emergency access / egress considerations, space requirements for mechanical / electrical equipment and the geometry of the various junctions between the tunnels.

The Excavation Sequences were designed according to the expected geology; the single or dual side wall drift method is used for the large Station Tunnels.

To design the initial and final lining, extensive numerical analyses were carried out.

Project Status

The final design of the Beacon Hill Tunnels and Station has been completed in December 2003. After a prequalification process, Sound Transit selected three qualified bidders:

- Kiewit/Traylor/Frontier-Kemper/Beton und Monierbau, A Joint Venture

- Impregilo-Healy-Alberici-Parsons, A Joint Venture

- Obayashi Corporation

The bids are due on May 14, 2004. NTP is expected for June and construction could start in Summer 2004.

Read More...

Two Papers about the Beacon Hill Station were written by staff of the Dr. Sauer Corporation:

Benchmark for the Future: The Largest SEM Soft Ground Tunnels in the United States for the Beacon Hill Station in Seattle

Jürgen Laubbichler, Dr. G. Sauer Corporation

Thomas Schwind, Dr. G. Sauer Corporation

Gerhard Urschitz, PE, Dr. G. Sauer Corporation

SEM / NATM Design & Contracting Strategies

Joseph Gildner, PE, Sound Transit

Gerhard Urschitz, PE, Dr. G. Sauer Corporation