You are here

Featured Projects - Brunel's Thames Tunnel

The rehabilitation of Marc Brunel's Thames Tunnel was undertaken over a 24 month period by WS Atkins and Dr. Sauer Company acting as a specialist tunnelling, shotcrete and waterproofing consultant, with the contract awarded to Taylor Woodrow Civil Engineering Ltd (TWCE).

Introduction

The Thames Tunnel was constructed between 1825 and 1843 and was the world's first bored tunnel river crossing. Approximately 400 m in length the tunnel runs between Wapping and Rotherhithe Stations and forms part of London Underground's (LUL) East London Line. The structure is located at a very shallow depth beneath the bed of the River Thames and is situated mostly in the Thames Gravel Deposits and Woolwich and Reading Beds.

The Existing Tunnel Structure

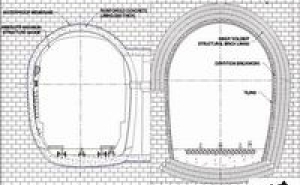

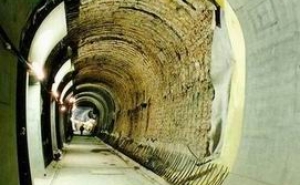

The brick tunnel has a rectangular section with twin side-by-side horseshoe inner tunnel profiles, linked by a series of cross passages at approximately 5 m centres. The inner profiles of the structural brickwork were lined with tiles to form a uniform cross section and provide a mechanism for constraining ground water.

The Refurbishment Scheme

Refurbishment was primarily aimed at tunnel strengthening and waterproofing with the construction of a new permanent inner lining.

The original scheme comprised filling the cross passages with structural blockwork with the twin bore tunnels strengthened using sprayed concrete techniques.

However, in April 1995 the structure gained Grade II listed status with the requirement to retain a section of tunnel in its preserved state. A design panel comprising LUL, Dr. G. Sauer Company and TWCE was convened to accommodate this constraint, with the final design based on a permanent reinforced concrete inner lining, formed using a specially fabricated steel shutter with a renovated section at Rotherhithe Station.

Design considerations and requirements

The permanent lining thickness was restricted in order to maintain the minimum structure gauge and kinematic envelope, with a waterproof membrane complete with geotextile fleece introduced between the permanent lining and existing brickwork.

Not withstanding this requirement a 'back of lining' drainage system was incorporated in the final design.

Structural analysis and design

Analysis of the tunnel lining was carried out using two-dimensional Finite Element methods. Provision was made for three-dimensional analysis in view of the presence of cross passages but in the event this was deemed not to be necessary.

Seven load cases were considered to cover various long term loading conditions, with the final design carried out in accordance with BS8110 Part 1:1985 and taking account of the maximum live and dynamic track loadings.

Construction

Following construction of the track slab throughout both tunnels and reconstruction of dip sumps, the cross passages were relined using a steel shutter which incorporated the original architectural features.

A 5.5 m long shutter for the main tunnel linings was in modular form, so that it could be shortened in areas where significant amounts of structural brickwork had to be removed to limit the length of tunnel affected.

Monitoring in the main tunnels during brick removal included tape convergence and load/deformation measurements using a temporary steel frame fitted with load cells and strain gauges.

Construction was successfully completed in the Spring of 1997.