You are here

Santiago's Metro Expands

Santiago's Metro Expands

NAT 2004

North American Tunneling Conference, April 17-21, 2004

Please follow this link to view the presentation (pdf)!

ABSTRACT

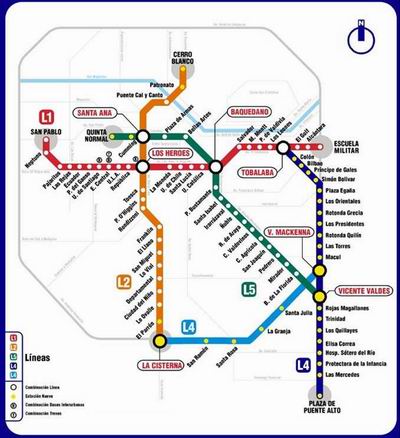

Metro de Santiago has planned an ambitious array of new projects for the period of 2000 through 2005, which will almost double the reach of Santiago's subway by late 2005 and bring service to an additional 1.8 million people. Metro is currently operating three rail lines with a total length of about 40km, of which 23km are below grade. New projects include the extension of two existing lines and construction of two new lines, which will increase the number of stations from currently 48 to 80. The subway operated by Metro S.A. is the backbone of the Urban Transportation Plan for Santiago (UTPS) which includes the extension of Line 2 to the north and to the south and Line 5 to the west, and foresees construction of Line 4 and Line 4A. All new or extended lines will be connected to bus transfer stations along the Metro system and, in addition, Line 5 will interface with a suburban railway line at a new intermodal terminal.

1 HISTORY

Construction at Metro Santiago started in the mid 1970s with underground portions mainly in cut and cover boxes. By the 1980s, increasing public objection to the surface disruption forced Metro to investigate less intrusive alternatives, such as mined tunnels. The subsequent development from cut and cover construction to mined running tunnels and mined stations has to be described as rapid. In 1993 the design of the initial Line 5 extension included the first mined tunnel experiment, a 2.0km long running tunnel portion under Baquedano Park. The tunnel design was produced by Ingendesa, a Chilean engineering firm with tunnel expertise gained from designing hydro electric power plants. The experiment proved to be successful however, at the second Line 5 Extension in 1997, a 2.8km continuation to the west the stakes for Metro were much higher. This time the alignment was planned beneath a heavily frequented street and adjacent to the city's 300 year old cathedral and other historic buildings. To minimize the risk Metro required the Chilean design firm Cade Idepe to utilize foreign tunnel expertise. This expertise was provided by Geoconsult of Austria, which developed a comprehensive design according to the principles of the New Austrian Tunneling Method (NATM) for the running tunnels. While the running tunnels for this Line 5 Extension were mined, cut and cover construction was still foreseen at the stations. With improved NATM techniques it even became viable and cost effective to mine stations which further reduced the environmental impact and added alignment flexibility. Therefore, based on a preliminary design by the Cade Idepe/Geoconsult team detailed mined tunnel designs for running tunnels and station tunnels for the extensions of Line 2 and Line 5 were developed in 2001. The mined approach was also chosen for the underground portions of the new Line 4 and a second extension of Line 2 to the North.

Figure 1. Metro system map.

2 EXTENSION OF EXISTING LINES

Currently Metro Santiago operates three lines, Line 1, Line 2 and Line 5. Line 4 currently under construction will be part of the expansion plan to be completed by the end of 2005. Line 3, planned to run parallel to the south of Line 1, was part of an earlier urban transportation plan which since has been revised due to the rapid development of the city.

The extension of Line 5 to the west of Santiago covers an underground length of 1.9km along Catedral Street and will feature two new stations. Quinta Normal Station, the western intermodal terminal will allow passengers to transfer to buses and a suburban railway line which runs in a north to south direction below Matucana Street. The neighborhoods along this line extension feature historic buildings with architectural and heritage value. Construction at Line 5 Extension commenced in May of 2001 and the completion of the work is expected by the end of 2003, with service to start by March 2004.

Figure 2. Area of Quinta Normal Station.

The initial extension of the existing Line 2 to the north has an underground length of 2.2km and two new stations. Running below Recoleta Street, the first extension crosses under the Mapocho River and Costanera Norte, a major urban highway under construction. Aside from preliminary work at shafts and access tunnels, construction for this line extension began in May 2001 and will be completed by mid 2004 with service expected to start in August of 2004. A second extension of Line 2 to the north is currently under design and will add 5.1km of underground rail and five stations to the system. The new section extends Line 2 to Avenida Américo Vespucio, a major ring road around Santiago and construction is planned to start in late spring of 2004.

Besides the addition to the north, Line 2 will also be extended 2.3km to the south, near the merging point of Gran Avenida José Miguel Carrera and the southern portion of Avenida Américo Vespucio. Two new stations will be constructed along the southern extension of Line 2. La Cisterna Station, the south terminal station, will be the link to Line 4, Metro's future expansion line currently under construction. Construction for the extension began in January 2002 and is expected to be completed by December 2004.

The preliminary and detailed designs for the line extensions were produced by the design team of Ingendesa, Arze, Reciné Asociados Ingenieros Consultores (ARA), two local engineering firms, and the Dr. G. Sauer Corporation (DSC) of Herndon, Virginia, as their expert foreign tunnel consultant, and the Cade Idepe/Geoconsult team.

3 NEW LINES

The planned two new lines for Metro's system will connect ten communities in the east and south of Greater Santiago through a total length of 33km of underground, at grade and elevated rail. Line 4, which extends from the existing Tobalaba Station on Line 1 to Puente Alto in the south, includes a 7.9km long tunnel section from Tobalaba Station to Rotonda Grecia. The 6.5km section from Rotonda Grecia to Avenida Vicuña Mackenna will be constructed at grade along the median of Avenida Américo Vespucio and a 0.6km long over-under tunnel section. From thereon the line will be constructed to Puente Alto mostly elevated along the alignment of Avenida Vicuñ¡ ackenna with some at-grade and underground portions.

The new Line 4 will also extend westward at Station Vicuna Mackenna to end at the termination of the southern extension of Line 2, La Cisterna Station. This branch, to be called Line 4A, will run at grade along the median of Avenida Américo Vespucio with a length of 7.9km.

Detailed designs for the underground portions of Line 4 were completed in July 2003. Three teams, Arcadis Geotecnica/Bureau de Projectos, Cade Idepe/Geoconsult and Ingendesa/ARA/DSC were involved in the designs of mined running tunnels and underground stations.

4 DESIGN AND CONSTRUCTION

4.1 Geology

Metro's existing and new lines lie in quaternary sediments of gravel, the so called "Grava de Santiago" or "Ripio de Santiago" (Ripio) and locally contain deposits of over-consolidated clays. In the north those sediments originated from the Mapocho River, while in the south the sediment's origin is the Maipo River. In the east sediments were deposited by erosive streams from ravines of the Cordillera de Los Andes.

In the Mapocho Deposit a superior 4.5 to 6.5m thick stratum of fluvial origin is followed by a stratum of fluvial-glacial deposits with similar gradation except the presence of plastic fines and a somewhat bigger compactness and cohesion. The groundwater level is variable, but generally located at approximately 80m depth. The Maipo Deposit is of fluvial origin and with similar properties as found in the second Mapocho Deposit, with a higher groundwater table at approximately 20m depth.

The sediments deposited by erosive streams from the Cordillera de Los Andes consist mainly of clay and silt with low to moderate plasticity and sand lenses of variable sizes. The material is partially saturated (30% to 75%) with the groundwater table within 20m of the surface. This deposit is interlocked with the ripio in a saw-tooth pattern along a contact line in north to south orientation. About 4.0km of the underground portion of Line 4 will be located in this formation.

Figure 3. Running tunnel during track work.

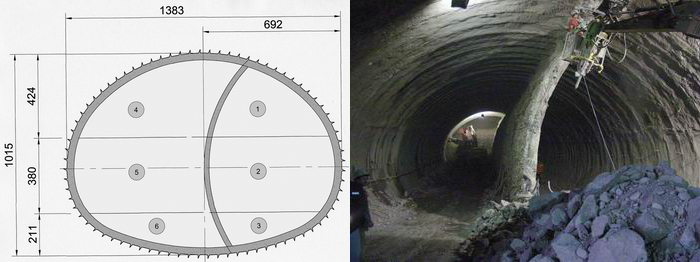

4.2 Running Tunnels

Metro's running tunnels are single tube, double track tunnels with an average cross section size between 60m² and 65m². Tunnel size, stable ground conditions and an overburden of approximately 9 to 11m allow for a full face excavation with a substantial earth wedge used for face stabilization as well as working platform during profiling, lattice girder and wire mesh installation and shotcete application. The average excavation round length is 1.0m with primary support comprising of 200mm initial shotcrete with lattice girder and wire mesh reinforcement followed by a secondary layer of shotcrete, 150mm thick, reinforced with wire mesh or rebar. Using data and experience gained on the Line 5 Extension the running tunnel linings have been reduced from a thickness of 500mm to the proposed 350mm to be used on the new lines and line extensions, a savings of 30%. The shotcrete used is typically dry shotcrete, however, wet shotcrete has been used at the Line 2 North Extension and is currently in use at Line 4. Steel fibers in lieu of wire mesh or rebar reinforcement have been considered at Line 4.

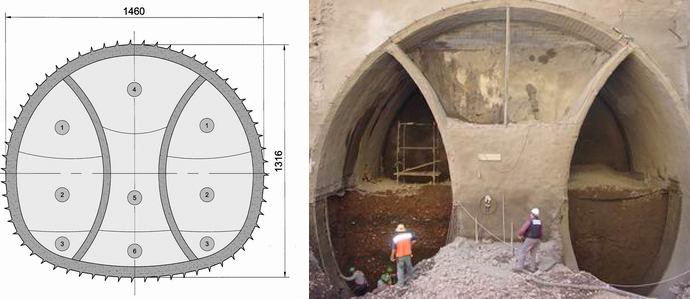

4.3 Station Tunnels

With a cross section size of up to 150m² and an overburden of as low as 7m the new station tunnels on the Santiago Metro produce some impressive underground structures. This impression is enhanced by perpendicular intersections with access tunnels of similar size. The design approaches to these massive caverns differ for each design team at the line extensions and also require an approach adapted to the clay dominated deposits at Line 4's Plaza Egaña Station and Los Orientales Station. There the final design team, Cade Idepe/Geoconsult has developed a binocular configuration for the 140m long station tunnels with a center pilot tunnel in which permanent central support columns are cast prior to the excavation of the station tunnels on each side.

On the extensions of Line 2 and Line 5 in the good quality ripio above the ground water table, the excavation of the station tunnels follows a top heading and bench/invert sequence with two side drift tunnels and a central gallery. At the El Parrón Station on the Line 2 South Extension the Ingendesa/ARA/DSC design team applied experience gained on the Line 5 Extension and modified the design to a single sidewall drift sequence. This approach was also applied to the design of Las Mercedes Station at Line 4 and was taken over by the Arcadis Geotecnica/Bureau de Projectos design team for their station detailed designs on the new line. The access tunnels at the line extensions were designed by Cade Idepe/Geoconsult as part of their preliminary design work with a full span top heading and bench/invert sequence. The wide span however requires pre-support using grouted pipe spiling and an earth wedge providing face support.

Besides the grouted pipe spiling on the full span top heading excavation and grouted pre-spiling, using self drilling bolts, for break-out situations from an access tunnel into a station tunnel, no significant pre-support is necessary in the ripio when appropriate excavation and support sequences are used. During excavation according to the designed excavation sequence, station tunnels just like the running tunnels generally receive a primary lining consisting of lattice girders, wire mesh and shotcrete of 300mm thickness. This initial support is followed by a secondary, 200mm thick shotcrete lining, to arrive at a combined thickness of 500mm for the Line 2 South Extension stations.

Figure 4. Double side wall drift station excavation.

No integrated waterproofing systems have been considered by Metro so far for either running tunnel or station tunnel designs.

4.4 Geotechnical Instrumentation Monitoring

Geotechnical instrumentation of the running tunnels comprises mainly of five point in-tunnel monitoring cross sections and seven point surface settlement sections at the same station. The in-tunnel convergence points and roof leveling points are read in three dimensions according to a specified reading schedule which considers the actual location of excavation face and work progress. The monitoring cross sections are laid out at 25m intervals along the alignment, which with today's extensive tunneling experience in the ripio is based on liability considerations rather than on geotechnical necessity. Monitoring points are also placed on sensitive structures within the zone of influence along the alignment.

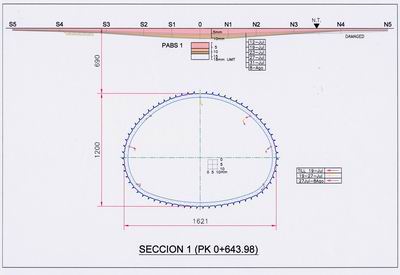

Figure 5. Single side wall drift station excavation.

At station tunnels the monitoring point configuration within a monitoring cross section varies based on excavation approach. In addition to deformation monitoring, strains and stresses on and in the shotcrete linings are measured using strain gages, ground pressure cells and concrete pressure cells. As part of an optimization effort of the whole instrumentation program, the use of sliding micrometers, extensometers and inclinometers was drastically reduced, once sufficient information and data regarding the behavior of the ripio was available. This effort has reduced the cost for instrumentation and monitoring to approximately $250,000 per km running tunnel.

The readings are taken by an independent geotechnical consultant, who transmits the processed data to the design engineers, construction supervision and Metro's project management team for further analysis. The processed data is then compared to threshold values and trigger values established by the engineers during the design. These values, although set slightly different by the individual design teams are based on mining sequence, geology and surface developments. The set limits of approximately 15mm for surface deformation above the station tunnel center line or 12mm for a roof leveling point on the station tunnel center line have so far not been exceeded during the ongoing line extension works.

Figure 6. Surface Settlements at Quinta Normal Station.

4.5 Execution of Work and Supervision

Metro's administrative set-up for construction contracts is predominantly design-bid-build. The design work generally starts with a preliminary design, which for reasons of time savings includes preparatory work such as the detailed designs for shafts and access tunnels. Detailed designers pick up at an approximate 30% level and remain involved throughout the construction process by furnishing construction supervision, which includes a monitoring engineer responsible for the interpretation of gathered and processed geotechnical instrumentation data. Based on the monitoring engineer's interpretation of the data and in coordination with the design team field modifications to the design can be made, if required. Another task of the construction supervision is to verify design compliance and to respond to contractor's questions regarding the design.

To supervise the actual construction activities Metro awards construction management and inspection contracts for the individual line sections. The construction management and inspection work includes quality assurance tasks, enforcement of safety requirements as well as tracking of construction progress and construction cost. The technical documentation and coordination with the independent geotechnical consultant regarding access to the tunnel for monitoring purposes are also responsibilities of the construction management and inspection team.

To date construction of Metro sections is mainly carried out by local contractors and Chilean subsidiaries of large foreign companies, such as Sacyr of Spain and Mendes Junior of Brazil. The quick adaptation by local contractors from cut and cover construction to mined tunneling methods is encouraging and current excavation rates of 3.0 to 4.0m per 24 hour day in the running tunnels are remarkable. The ground with its extended unsupported stand-up time could allow excavation rounds beyond the current 1.0m to expedite the construction. However, the use of specialized currently not utilized tunnel equipment, such as excavators with articulating arms, man-lifts and a more efficient mucking operation would increase productivity without compromising the current low level of risk.

Figure 7. Quinta Normal Station excavation.

The use of fully mechanized excavation equipment was considered for the Line 4 construction and several studies were commissioned by Metro to investigate the technical and economical feasibility of Tunnel Boring Machines (TBM) and Earth Pressure Balance Machines (EPBM) for the clay zones and water bearing zones near the San Carlos Canal in the east and the Maipo River in the south. All studies concluded that while technically feasible there is no cost or schedule advantage using fully mechanized excavation equipment on the 7.9km long underground stretch from the existing Station Tobalaba to Station Rotonda Grecia or elsewhere along Line 4. In fact the studies concluded that there is a considerable lower risk to the schedule using NATM.

5 CONSTRUCTION COST

One of the reasons for the success of NATM on Santiago's Metro was the cost savings realized after its introduction. While the first tunnel section under Bustamante Park proved that mined tunnels are technically feasible and caused less disruption to the city, the construction cost were approximately 20% higher compared with cut and cover structures, not considering costs for utility relocation and expropriation. Today, after further improvements to the NATM designs, the construction cost average about $6,500 per linear meter of running tunnel and about $27,500 per linear meter of station tunnel. At present, the cost of the new Line 5 Extension is about 40% less compared to the Line 5 Extension built in the late 1990s. The reasons for the reduction in cost are more favorable ground conditions, lower rise buildings along the alignment and most important the conversion of expensive and disruptive open cut stations into mined stations. Metro hopes to reduce this already low tunneling cost even further during the construction of the new Line 4 by introducing value engineering as a tool for the contractors to optimize the designs.

6 CONCLUSION

Not enough can be said about the fast development of Santiago's Metro from cut and cover construction in the middle of an almost 5 million people metropolis to mined tunnels at reduced cost. Within approximately 10 years the local design and construction community with support of foreign experts has learned to develop and execute complex NATM designs for large underground spaces. There is no argument that the favorable ground conditions and a low water table have helped engineers and contractors in their swift learning process. However, one has to laude Metro's balanced approach between their desire to reduce construction cost and their willingness to take risk. While the replacement of running tunnels with cut and cover boxes by mined tunnels in the early 1990's was a successful first step, Metro's managers understood that with foreign tunnel expertise even bigger steps could be made. Thus in 1997 foreign NATM expertise was brought in for the design of the running tunnels during the second Line 5 Extension. This proved to be just the beginning of a prolonged success for the sequential excavation method on Santiago's Metro, where today all underground work is carried out using this method. Advantages such as lower cost and lower risk gave NATM also the edge over mechanized excavation methods, which were considered for the new Line 4 construction. With room for even further improvement of productivity through efficient construction equipment, one can only look forward to future line extensions and new lines in Santiago.

7 REFERENCES

Wallis, S., 2003a. "Evolving NATM for Santiago's Metro", T&T International, March 2003.

Wallis, S., 2003b. "Metro's evolution", T&T International, April 2003.

Mercado, C., 2003. "Tecnologia sobre Rieles", Revista Bit, September 2003.

Click here to see the full document (application/pdf, 302 KB).