You are here

Berry Street Tunnel

| Owner: | |||||

| Client: | |||||

| Service: | Value engineering design and construction supervision

|

||||

| Estimated cost: | Commencement: | September 27, 1996

|

Completion date: | December 28, 1997

|

|

| Location: | Pittsburgh, PA United States |

||||

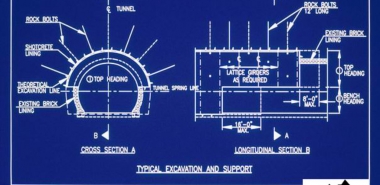

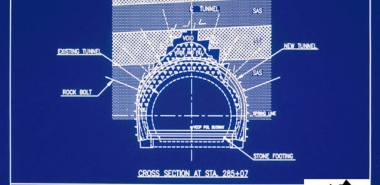

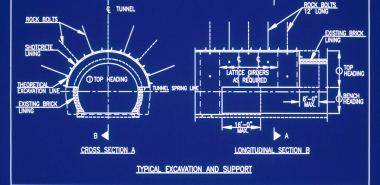

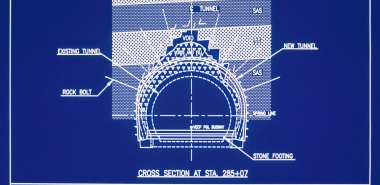

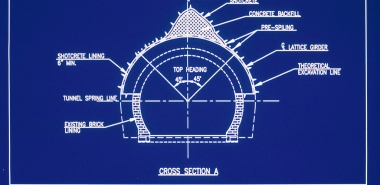

| Technical data: | Enlargement of a 2,800 ft (853 m) long, two laned brick lined tunnel to a 34 ft (10 m) wide horseshoe shaped tunnel with approx. 150 ft (46 m) of overburden. Primary lining: steel fibre reinforced shotcrete and lattice girders. Waterproof membrane with an unreinforced concrete secondary lining. |

||||

| Geology description: | Medium hard to soft sandstone and shale with thin beds of coal and claystone, non-cohesive fill of the original cut and cover section. |

||||

| Geology types: | |||||

| Categories: | |||||

| Bid cost: | Final cost: | $18,000,000

|

|||

| Service areas: | |||||

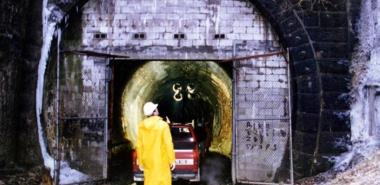

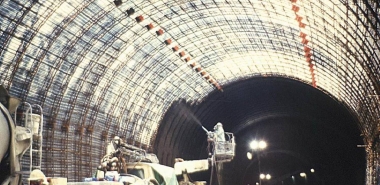

The original tunnel was built in 1865 as a 12 ft wide (4 m) single-track rail tunnel. It was widened in 1873 to 25 ft (8 m) double-track with a 26 in-thick (66 cm), brick-lined horseshoe design. After several structural repairs, mainly for spalling bricks, it was finally closed in the early 1960s. More than 30 years later the Port Authority of Allegheny County saw benefits in adapting the former railroad alignment and right of way to its new bus way connection between downtown Pittsburgh and the new Pittsburgh International Airport. A NATM value engineered proposal in the tunnel refurbishment contract provided US $ 2 mil cost savings compared to the original bid. The redesign was based on elevating the tunnel alignment so that the future tunnel crown could be excavated in better ground conditions and on changing the proposed horseshoe to a "rounded" cross section. This combined with the utilization of the NATM allowed a 40 % reduction in shotcrete thickness, a 22 % reduction in concrete lining thickness and the elimination of the reinforcement in the final lining. Furthermore, the NATM proposal eliminated pre-excavation grouting (200,000 bags of cement) and over 10,000 rock bolts while reducing lining thickness. During tunneling up to three headings were excavated simultaneously, one from each portal and one started within the tunnel, averaging a total excavation progress of 15.4 ft (4.7 m) /24h day. Following waterproofing, the concrete lining was completed 16 month after beginning of the reconstruction.