You are here

MBTA, Russia Wharf Segment, Section CC03A

| Owner: | |||||

| Client: | |||||

| Service: | NATM detailed design and site supervision during construction.

|

||||

| Estimated cost: | Commencement: | December 28, 1996

|

Completion date: | December 19, 2004

|

|

| Location: | Boston Boston, MD 02101 United States |

||||

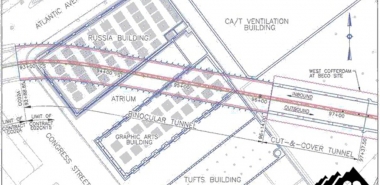

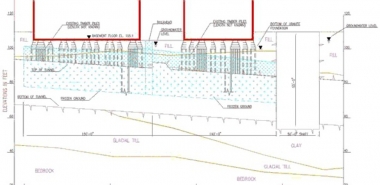

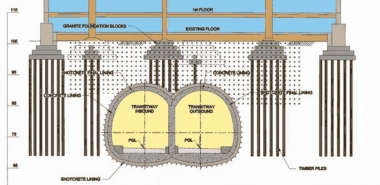

| Technical data: | Road tunnel with 2 lanes and a lenght of 400 ft. Study into the construction of either a single tunnel or a binocular tunnel with central pier using the shotcrete support method with ground freezing pre-support to protect overlying historic building. |

||||

| Geology description: | Made ground, peat, glacial till (cohesive, plastic). The peat horizon undulates along the route, in places it is expected to be exposed in the top half of the proposed tunnel face. |

||||

| Geology types: | |||||

| Categories: | |||||

| Bid cost: | Final cost: | $18 million USD

|

|||

| Service areas: | |||||

| Construction methods: | |||||

| Tunneling under: | |||||

| Groundwater control: | |||||

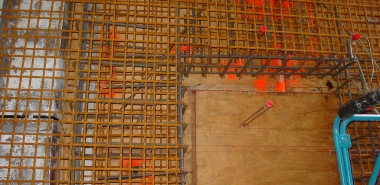

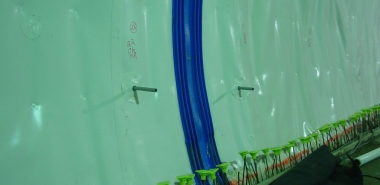

The Russia Wharf segment is the last, but most challenging section of the Silverline Phase II construction for the Massachusetts Bay Transportation Authority (MBTA). The line is designed to provide a dualmode bus rapid transit connection between the central business district in South Boston to the new Convention Center. The tunnel passes diagonally under the 100 year old Russia Wharf complex, which comprises three seven-story buildings with steel frames and brick facades listed in the National Register of Historic Places. The chosen construction method was NATM in conjunction with ground freezing, for the first time in the US. Steel fibre reinforced concrete was used for temporary and permanent lining.